Top Insights

- Siemens Poland needed to streamline the communication system of their MAG6000 flow meters for real-time data transmission.

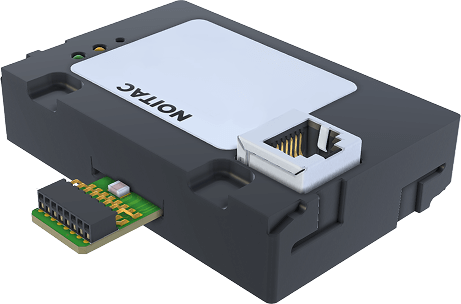

- NOITAC developed a custom PROFINET communication module to improve data accuracy and reduce complexity.

- The solution provided real-time data, simplified the system, and allowed Siemens to easily scale the solution across installations.

The Challenge

Siemens Poland needed a way to integrate PROFINET communication with their MAG6000 flow meters to achieve real-time data collection and streamline communication between devices. Their existing setup was overly complex, relying on multiple communication devices that increased costs and maintenance.

The Solution

NOITAC created a custom PROFINET communication module that streamlined Siemens’ industrial network, reducing the need for additional communication devices. The solution utilized PROFINET, Ethernet, and CAN technologies, and the system was programmed using C/C++, Python, and PLC languages. This integration allowed Siemens to benefit from real-time data transmission and scalable, efficient communication.

Results

- Improved real-time data accuracy, enhancing operational control.

- Reduced costs and simplified maintenance by decreasing system complexity.

- Scalability, allowing the solution to be expanded across different Siemens installations.